Save Your Desk! How to Prevent & Fix Mic Arm Damage

Table of Contents

The Frustrating Problem: Damaged Desks

You excitedly unpack your new mic arm, ready to improve your audio setup. It promises stability and clean desk lines, thanks to the protective padding on the clamp. But weeks or months later, you move the gear... only to find ugly marks beneath. Scratches, dents, maybe even crushed wood grain.

The shock hits: "Why did both my mic arms ruin my desk?"

This isn't just bad luck – it's a shared headache countless streamers, podcasters, and remote workers face. That little foam pad, often thin and basic, clearly fell short. Your once-pristine workspace now sadly wears the scars from your essential equipment.

The promise of that clamp padding feels misleading. It's supposed to be the shield. Yet, despite its presence, the damage happens. The problem often lies in that padding material itself.

Sometimes it’s just too thin, compressing flat under pressure until it offers little real cushion. It might be poor-quality foam that breaks down and turns brittle over time. Or perhaps it didn’t fully cover the sharp metal edges beneath. Worst of all, on slightly uneven desks or with overtightening, the pad can shift entirely, leaving metal to bite directly into the wood or laminate surface. That small layer of protection failed – and your desk paid the price. The promised safety net simply wasn’t enough.

Why Padding Isn't Always Enough

Thin/Low-Quality Foam Compressing Over Time

That soft protective pad under your mic arm clamp might look reassuring, but often it’s too thin or made from weak materials. Over weeks of pressure, basic foam can flatten like a deflated cushion – losing its ability to absorb shocks. This isn't just wear and tear; some padding simply crushes under constant strain, turning paper-thin and useless. Before long, it offers no real barrier. Metal meets wood, and damage becomes almost guaranteed.

Uneven Desk Surfaces → Uneven Pressure

Think your desk is perfectly flat?

Think again. Many desks (especially laminated or budget wood surfaces) have invisible dips or bumps. When the mic arm clamp presses down, padding designed for smooth surfaces won't adapt. Instead, it might grip tightly on high points while floating loosely over low ones.

This uneven pressure leaves parts of the clamp exposed. Without cushioning, these pressure points act like tiny knives – concentrating force and digging grooves or dents you won't notice until it's too late.

Mic Arm Weight Distribution Flaws

Your mic arm is heavier than it looks. Every movement – swiveling toward your mouth, raising it for standing use – shifts its center of gravity. This dynamic weight pushes unevenly on the clamp, especially if the arm is extended far out.

Basic padding often can't handle this shifting load. It might grip firmly when static but slide or deform during adjustments, letting metal grind against the desk. It's like trying to balance a chair on two legs instead of four; unpredictable leverage = stress points.

Overtightening Clamps = The Hidden Culprit

"Tighter is safer," right? Wrong. Over-cranking that clamp knob is arguably the biggest cause of hidden damage. When you overtighten, two bad things happen:

- Thin padding compresses unnaturally, thinning until it fails

- The clamp metal actually cuts through weak material

Think of squeezing a sponge until it tears – the padding loses integrity, and the clamp’s hard edges win. This creates deep indents or cracks, especially on softer woods or particleboard. Worst part? You might not see it until unclamping.

So what now? If your padding has failed, rest assured it's rarely just "bad luck." The good news? Solutions exist – starting with smarter padding, placement, and clamping habits.

5 Ways to Prevent Future Damage

Upgrade to Thick Rubber/Felt Pads (DIY or Aftermarket)

Don’t trust flimsy factory foam. Replace it with dense rubber pads (3mm-5mm thick) or industrial felt cut to size. These compress less under pressure and absorb shifting weight.

- DIY: Buy self-adhesive rubber sheets online; trace your clamp base, cut, and stick.

- Aftermarket: Look for "mic arm isolation pads" designed for vibration and pressure damping.

Pro Insight: Rubber outperforms foam long-term – it rebounds instead of flattening.

Use a Dedicated Clamp Plate or Metal Bracket

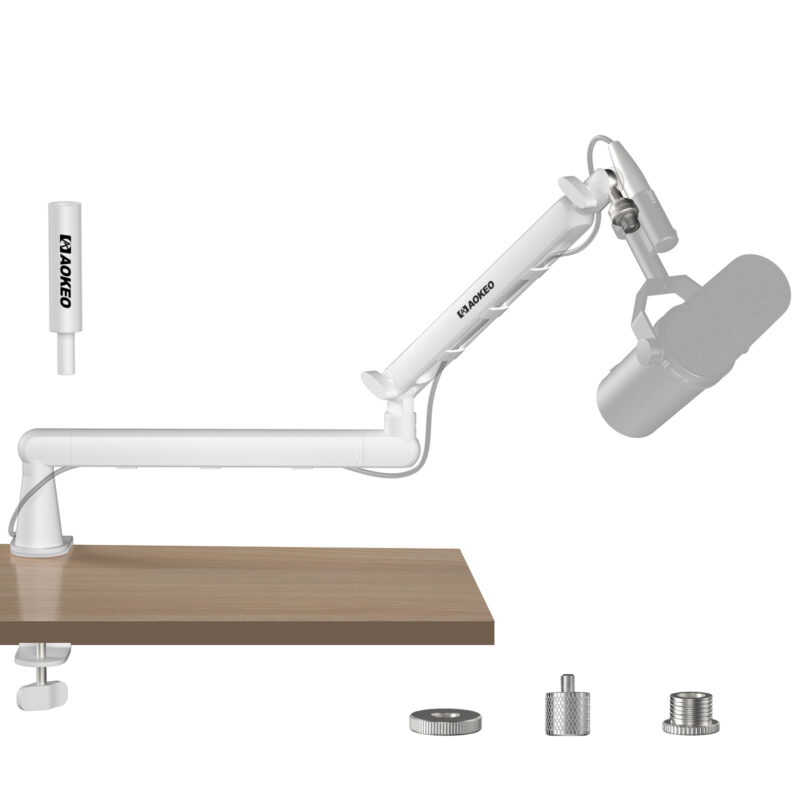

AK55 Low Profile Mic Arm

Adjustable Microphone Arm Stand

Aokeo AK-55 Low-Profile Mic Arm features a 360° rotating adjustable boom stand, ideal for Blue Yeti, Snowball iCE, HyperX QuadCast, and more. Designed for gaming, podcasting, recording, and streaming, it fits tables up to 7cm thick, ensuring a sturdy and flexible setup for any workspace.

AK55 Low Profile Mic Arm White

Aokeo AK-55 Microphone Arm offers a low-profile, studio-quality adjustable boom arm with 360° rotation. It provides robust support for popular mics such as Blue Yeti, Snowball iCE, HyperX QuadCast, SoloCast, and Elgato Wave. Featuring an easy clamp, this universal mic arm is ideal for streaming, podcasting, and gaming setups.

Spread the load! A steel or aluminum plate (e.g., 4"x4" or larger) between your clamp and desk distributes weight over a wider area, preventing dents.

- Place it UNDER your desk lip if possible for hidden support.

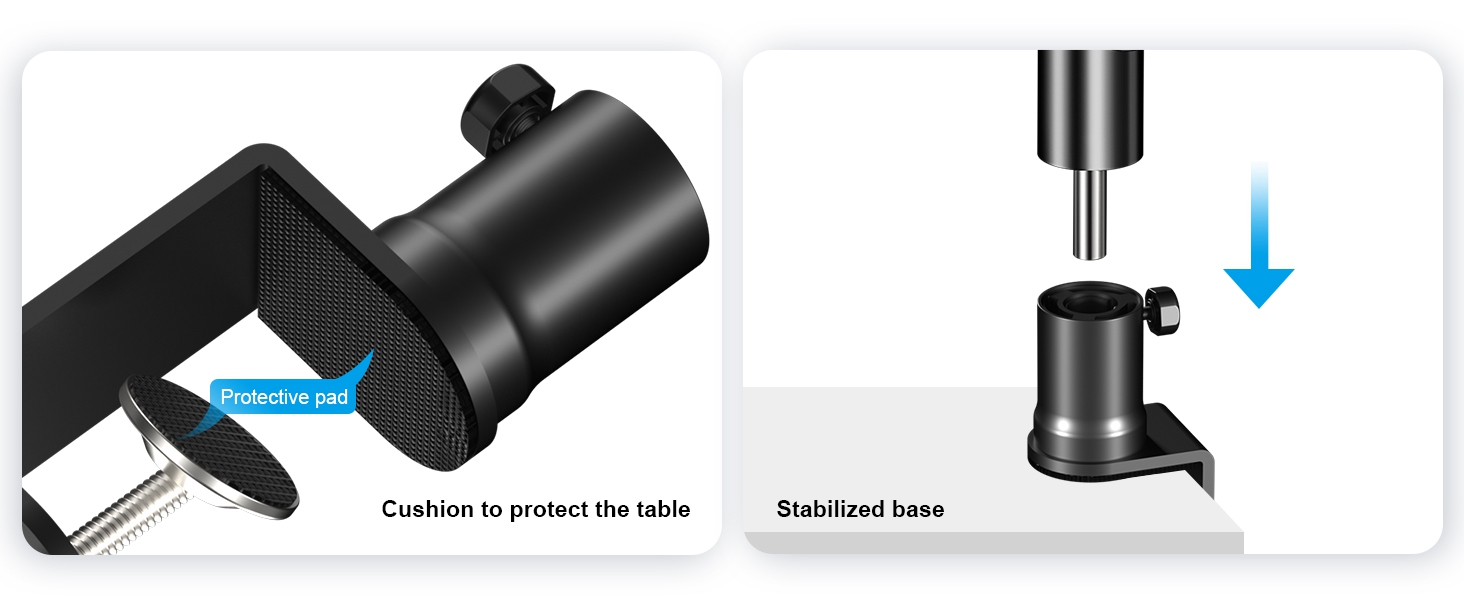

- Brands like Aokeo, incorporate protective rubber pads into their clamp designs to further prevent scratches or wear.

Try Non-Slip Drawer Liner Under the Clamp Base

Grip + cushion for $5. Cut a square of rubberized shelf/drawer liner. Layer 2-3 pieces if needed for thickness.

- Ensures the clamp won’t slide, reducing

- Adds shock absorption without adhesive residue.

Bonus: Liner grips uneven surfaces better than hard pads.

Check Clamp Tension Weekly – Tighten Only Until Secure

Stop overtightening! Clamps only need enough tension to prevent wobbling – not "vice grip" force.

- Loosen knob fully, position arm.

- Hand-tighten until movement stops.

- Give just one extra quarter-turn– no more.

Test: If the arm holds position when extended, it’s tight enough. Cranking further only crushes padding.

Place Mic Arms Near Desk Frames

Find the bones. Position clamps directly over structural beams (usually beneath desk edges) – not weaker center spans.

Why: Particleboard surfaces flex. Steel frames resist denting. Even laminate tops are 3x stronger along reinforced edges.

Quick Prevention Checklist:

✅ Upgrade padding

✅ Distribute weight (plate/liner)

✅ Gentle tension + weekly checks

✅ Smart placement near beams

No magic foam will save a poorly positioned, overtightened clamp. Combine these tactics for bulletproof protection.

Fixing Existing Damage: Quick DIY Repair Tricks

- Got light scratches? Try gently rubbing the affected area with a walnut – the natural oils can help hide those small imperfections! Specialized wood touch-up pens are another simple fix.

- Dealing with a dent in unfinished wood? Lightly steaming the dent first, followed by careful application with an iron on a low setting, can sometimes coax the wood fibers back into shape.

- Deep dents or splinters are a bigger problem. For these, applying wood filler is your best bet. Once dried and sanded smooth, use a matching touch-up finish to conceal the repair.

- Looking at damage that's too hard or costly to fix? Don't worry! Chic desk mats beautifully cover larger areas right where your mic sits, or you can securely attach clamp plates directly over the arm's base to hide ugly scars.

Final Checklist: Protect Your Setup

Keep your mic arm and desk looking great long-term! Always use quality rubber padding, check mounts regularly for any signs of shifting or wear, place clamps properly avoiding edges, and tighten them gently – just enough to create a very stable hold. For heavy use, think about getting desk shields for ultimate surface protection.

→ P.S. Here's a bonus: Every Aokeo mic arm includes a tough, reinforced rubber base for instant grip – one less thing to worry about! Keep rocking your setup.